1.2 Ship Construction – Transverse Framing System

Ship Construction – Transverse Framing System

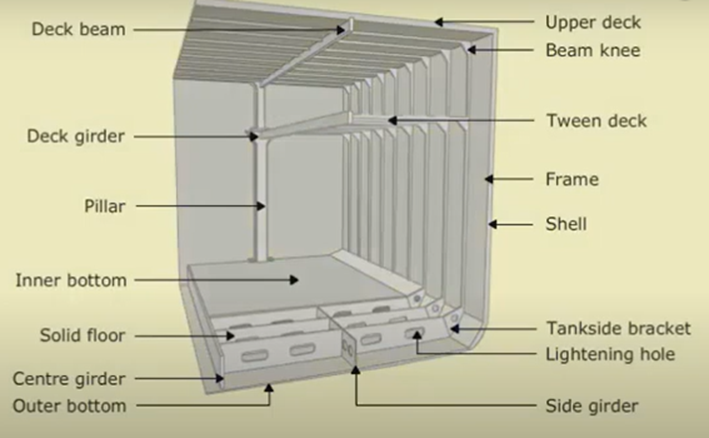

Transverse framing is a ship construction method where the primary structural members are closely spaced frames running transversely across the ship's hull. This system is commonly used in smaller vessels and those subjected to less severe longitudinal bending moments.

Components of a Transverse Framing System

Frames: Vertical members that run transversely across the ship's hull, providing transverse strength and rigidity. They are typically spaced at intervals of 600mm to 900mm.

Web Frames: Larger frames located at specific intervals, providing additional support and rigidity.

Girders: Horizontal members that run longitudinally along the ship's length, connecting the frames and providing longitudinal strength.

Beams: Horizontal members that support the deck plating and transfer loads to the frames.

Deck Plating: The steel plates that form the deck of the ship.

Side Shell Plating: The steel plates that form the sides of the ship's hull.

Bottom Plating: The steel plates that form the bottom of the ship's hull.