3.3. Stowage planning

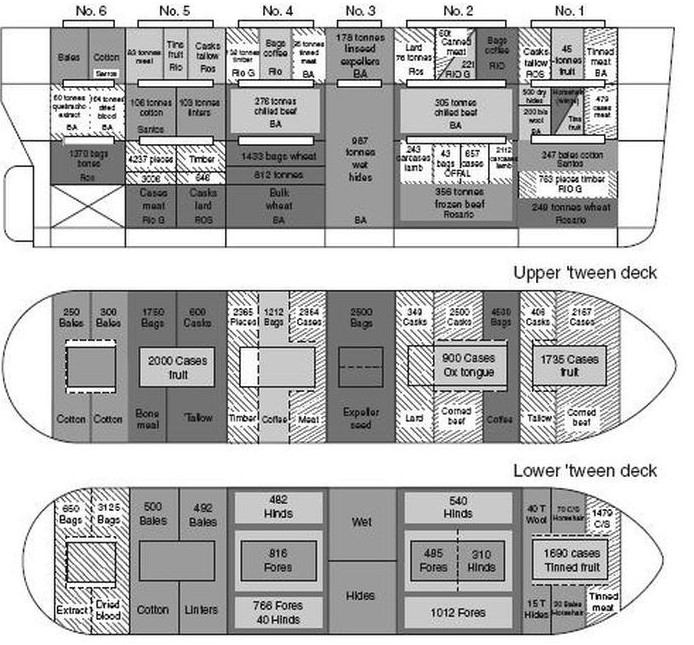

Stowage planning is the process of strategically arranging cargo on a vessel to maximize space efficiency, maintain stability, ensure safety, and comply with regulatory requirements. It is a critical part of maritime logistics, especially for container ships, bulk carriers, and general cargo vessels. Stowage planning aims to optimize the use of a ship's cargo hold by determining the best placement for different types of goods while considering various factors such as weight distribution, the ship's center of gravity, cargo protection, and the order of loading or unloading at different ports.

Stowage planning is the process of strategically arranging cargo on a vessel to maximize space efficiency, maintain stability, ensure safety, and comply with regulatory requirements. It is a critical part of maritime logistics, especially for container ships, bulk carriers, and general cargo vessels. Stowage planning aims to optimize the use of a ship's cargo hold by determining the best placement for different types of goods while considering various factors such as weight distribution, the ship's center of gravity, cargo protection, and the order of loading or unloading at different ports.

A well-prepared stowage plan takes into account the type of cargo, its weight, volume, destination, and handling requirements. Heavy items are typically placed lower in the vessel to ensure stability, while dangerous goods must be stored in compliance with international safety regulations to prevent accidents or contamination. Additionally, the plan ensures that the cargo to be discharged first is easily accessible to reduce port turnaround time.

Stowage planning involves collaboration between ship operators, port authorities, and logistics teams, and often employs software tools that simulate various loading configurations, optimizing space while adhering to safety and operational constraints. Proper stowage planning is essential for reducing operational costs, ensuring timely deliveries, and maintaining the safety of both the crew and the cargo.

A good plan minimizes the risk of cargo damage, reduces fuel consumption, and complies with international maritime safety standards such as the International Maritime Organization (IMO) regulations.